Your Position: Home - Other Metals & Metal Products - Advantages of metal corrugated pipe culverts in highway engineering

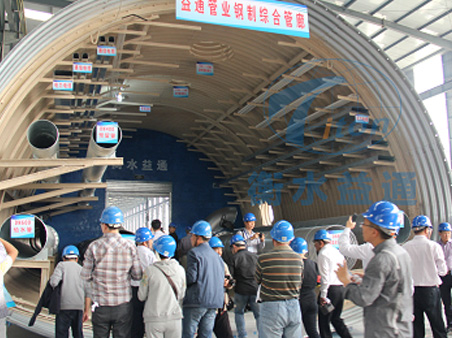

Metal corrugated pipe culverts are one of the new technologies promoted in highway engineering projects in my country in recent years. It is to press 2.0-8.0mm high-strength thin steel plates into corrugated steel, and then roll them into pipe sections according to different pipe diameters to replace reinforced concrete culverts. The installation period of corrugated pipe culverts is only 3-20 days, which saves more than one month of construction period compared with concrete cover culverts and box culverts. It has a wide range of applications and obvious social and economic benefits.

Strong anti-deformation and anti-settlement ability

Highways built in coal mine goaf areas can cause different degrees of ground drop and uneven settlement due to underground goaf, which will cause different degrees of damage to general cement structures. Steel corrugated steel pipe culvert is a flexible structure. The corrugated steel pipe has the excellent characteristics of lateral compensation displacement in structure. It can give full play to the characteristics of strong tensile strength and excellent deformation performance of steel, and has greater anti-deformation and anti-settlement ability. It is especially suitable for places with low bearing capacity of soft soil, expansive land, collapsible loess foundation and places prone to earthquakes.

High corrosion resistance

Corrugated pipe culverts have higher corrosion resistance than traditional reinforced concrete pipe culverts. The pipe joints are hot-dip galvanized, and the ports are sprayed with asphalt for anti-corrosion treatment. It solves the problem of damage to concrete structures in humid areas in the south and cold areas in the north, and its effective working life is longer than that of traditional culverts.

Environmental protection and low carbon

Metal corrugated pipe culverts reduce or completely abandon the use of conventional building materials such as cement, medium-coarse sand, gravel, and wood. Metal corrugated pipe culverts are made of green and pollution-free materials, which is beneficial to environmental protection and reduces carbon emissions.

Fast opening time and convenient maintenance

Corrugated metal pipe culverts can be completed within one day from excavation to backfilling. Compared with traditional reinforced concrete structures, it greatly saves construction time and greatly reduces construction period consumption costs. Metal corrugated pipe culverts are easy to maintain in the later stage, and even do not need maintenance in a considerable part of the environment, which greatly reduces maintenance costs and has outstanding economic benefits.

In summary

Metal corrugated pipe culverts have the characteristics of short installation and construction period, fast traffic time, convenient maintenance, low carbon and environmental protection, high corrosion resistance, high deformation and corrosion resistance in highway engineering. In highway engineering construction, the use of corrugated pipe culverts can also make the road transportation efficiency unaffected, and at the same time, it can also strengthen its application in maintenance engineering, with significant social benefits.

9

0

0

Previous: None

Comments

All Comments (0)